Buy zinc ingots

It is obvious that the purchase of zinc ingots is of particular importance as a vital step in the supply and production chain. This stage plays an essential role and decision-making in industrial and production processes. Buying zinc ingots is not only related to financial and economic aspects, but also requires technical knowledge and a detailed knowledge of the required characteristics, standards and quality.

In this article, an in-depth review and analysis of the issues and challenges related to the purchase of zinc ingots will be done. This review will include the evaluation of criteria and standards necessary for the selection and purchase of zinc ingots, optimal methods for evaluating the quality and characteristics of zinc ingots.

This information can serve as a practical and useful guide to decision makers and experts in various industries, including metals, electronics, construction and other industrial fields.

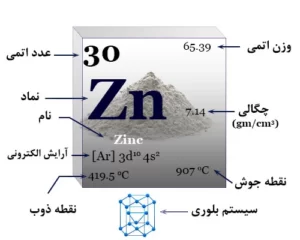

Zinc element

Zinc is one of the chemical elements in the periodic table known by the symbol “Zn” and atomic number 30. This element appears in the standard form of silver and white metal. One of the interesting features of zinc is its resistance to corrosion and rust. This metal, exposed to air and moisture, covers its surface with an oxide layer that prevents corrosion and rust. Another important characteristic of zinc is its high specific gravity, which distinguishes it from other metals. Also, this element has a high temperature melting point and boiling point, which makes it usable in different conditions, in different industries and different processes. Also, zinc is one of the metals that is flexible in its natural state and can be produced in the form of thin sheets and metals with different shapes.

History of zinc

Zinc is one of the chemical elements that has a very long history and was used in ancient times. Since ancient times, humans were aware of the metallic properties of zinc. In ancient Egypt, the element zinc was known as one of the materials used in the preparation of the mummy configuration. The Egyptians took advantage of the protective properties of zinc and used it to protect various mummified bodies.Due to its corrosion resistance and protective properties, this metal was used in various industries in ancient times and played an important role in the production and preparation of objects and works of art. Also, in ancient Greece, its anti-rust properties were used in the preparation of metal water traps. In ancient times, zinc was mostly used for metal applications, and they benefited from its corrosion-resistant and anti-rust properties. These uses in those times show the value and wide use of zinc in industries and daily life.

Applications of zinc ingots in various industries

Zinc is used as one of the metal elements with wide applications in various industries. This metal is used in various industries due to its properties such as corrosion resistance and rust resistance. The following examples can be used for zinc applications in various industries:

Electronics industry

The electronics industry is one of the basic materials used in the production of electronic components, including the production of transistors, diodes and other electronic components that are used to make electronic equipment.

Automotive industry

In the automotive industry, zinc is used as one of the important elements in the production of car parts. Among its applications, we can mention the manufacture of rust-resistant parts and for covering various parts, including the parts inside cars.

Manufacturing industries and machinery

Zinc is used in manufacturing and machinery industries as a coating and anti-rust on parts and equipment. These uses increase the resistance of parts against corrosion and make them more durable. It is also used in the production of brass and nickel alloys. By adding zinc to these alloys, their mechanical and resistance properties are improved. In casting industries, adding zinc to casting molds improves the accuracy and durability of the molds and preserves the shape and properties of the parts.

power plant industry

In the power plant industry, zinc is also used as a coating on parts that are exposed to harsh environmental conditions. These applications increase the durability and useful life of components used in power plants.

Chemical industry

One of the applications of zinc metal is in the production of zinc oxide. In the rubber industry, it increases the resistance of rubber against corrosion and preserves its physical properties, and it is used in the preparation of some medical ointments and creams, due to the antiseptic and antibacterial properties of zinc.

Important features of zinc ingots

Zinc ingot is one of the important and vital products in the metal industry, which has unique characteristics that have made it a useful and interesting material in various industries.

Its resistance to corrosion

Zinc ingot is known as a metal resistant to rust and corrosion, which makes it very valuable in applications that require products with long life and high strength.

Ability to process and shape

This metal has a good ability in various processes such as casting, shaping and production of parts, which increases efficiency and accuracy in the final production of products.

Resistance to temperature and thermal changes

It is used in some industries that require resistant materials in different temperature conditions.

Types of zinc ingots

Zinc ingots are produced with different grades and purity. The elements that make up the ingot include lead, cadmium and iron. They include the following:

The degree of purity is 99.99%

The degree of purity is 99.98%

The degree of purity is 99.97%

The degree of purity is 99.96%

The degree of purity is 99.95% (which is one of the best-selling types of ingots.)

The size of the ingot is 40 x 20 cm and the weight is approximately 25 kg, which is mainly supplied in pallets of one ton or more. The purity of zinc ingots has a great impact on the price. To buy zinc ingots, it is important to choose the right option by knowing the required purity percentage and the desired product.

The degree of purity is 99.99%

The degree of purity is 99.98%

The degree of purity is 99.97%

The degree of purity is 99.96%

The degree of purity is 99.95% (which is one of the best-selling types of ingots.)

The size of the ingot is 40 x 20 cm and the weight is approximately 25 kg, which is mainly supplied in pallets of one ton or more. The purity of zinc ingots has a great impact on the price. To buy zinc ingots, it is important to choose the right option by knowing the required purity percentage and the desired product.

Specifications for buying zinc ingots

Some important points to keep in mind when buying zinc ingots:

1- Purity

The purity of zinc ingot is of great importance and indicates the quality and ultimate usability of the metal. High purity usually means higher quality and better performance.

2- Size and dimensions

The dimensions and size of the zinc ingot should also match your needs. It depends on the final applications of the ingot.

3- Mechanical properties

The mechanical properties of the metal should also be checked. Resistance to bending, stretching and wear are important.

4- Surface quality

The metal surface should be checked; Is it of good quality and is it suitable in terms of cleanliness and smoothness or not?

5- Resources and suppliers

Choose a reliable and reliable supplier, which offers quality and standard metal.