Zinc ingot products

Pure electrolytic zinc ingot

Our ingot products with grades 98, 97 and 99 are produced from the best raw materials and basic and up-to-date methods. These high-quality ingots are used in various industries such as electronic industries, coating and production of special zinc-based alloys. We are also proud that our products are produced in the country and with strict quality control, they bring trust and confidence to our customers.

Zinc ingot with 99.99% purity Grade 99

This product is the purest type of bullion, which is called grade 99, and the total amount of impurities, which according to the standard includes elements of lead, iron, cadmium and copper, will be less than 100 ppm. Its main uses are in the production of alloys such as Zamak (aluminum-zinc alloy), coating methods such as cold plating or cold galvanizing, etc. This type of bullion has higher prices than other grades due to complex production methods with higher costs.

Zinc ingot with a purity of 98.99% Grade 98

If the total amount of impurities in the ingot is less than 200ppm, the produced ingot is placed in this group and is called grade 98.

Considering the much lower prices of grade 98 compared to grade 99, in industries that do not require high purity of zinc ingots, such as hot-dip galvanized brush steel coating units or some producers of brass ingots and sections whose products are relatively high sensitivity to the amount of impurities Zinc ingots are used, this type of ingot can be used

Zinc ingot with a purity of 97.99% Grade 97

If the total impurities of the ingot is less than 300 ppm, the produced ingot is placed in this group and is called grade 97. In general, it can be said that grades 98 and 97 have relatively similar uses, and due to the low price difference between the two, consumer units, taking into account the market inventory and the chemical analysis considered by their production managers, use one or both of the mentioned grades in their production lines. They use themselves.

Zinc ingot with a purity of less than 97.99% off grid

If the total impurities in the ingot are more than 300 ppm, the produced ingot is placed in this group, which is called off-grade ingot. It is obvious that this ingot is mostly used by units whose production process is less sensitive to the impurities in it. This type of ingot due to its lower price than other grades; It has a high demand from the units that consume it, which, of course, considering the progress of ingot production technology in Iran and the small supply of these low purity ingots, The mentioned units are sometimes forced to use ingots with higher purity such as grade 97.

Characteristics of the chemical composition of zinc ingots

Applications of zinc ingots

|

Composition |

Zn 99.99 |

Zn 99.98 |

Zn 99.97 |

row |

title |

|---|---|---|---|---|---|

|

(Zinc) Zn |

99/99 |

99/98 |

99/97 |

1 |

hot galvanizing |

|

(Lead) Pb |

0/005 |

0/013 |

0/025 |

2 |

Electro galvanization |

|

(Cadmium) Cd |

0/003 |

0/009 |

0/01 |

3 |

Zinc Oxide |

|

(Iron) Fe |

0/003 |

0/009 |

0/012 |

4 |

Zinc Plate |

|

(Copper) CU |

0/002 |

0/002 |

0/002 |

5 |

Sacrificial Anode |

|

(Tin) Sn |

0/001 |

0/002 |

0/003 |

6 |

Brass and Zamak alloys |

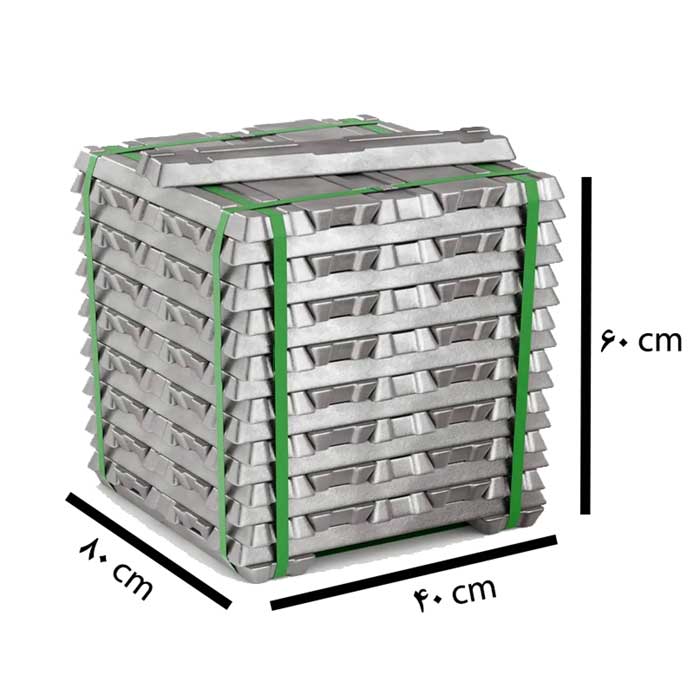

Packaging of zinc ingots

|

title |

amount |

|---|---|

|

Zinc ingot mold dimensions (cm) |

40 x 20 x 6 |

|

Zinc ingot weight (kg) |

25 |

|

The number of molds per bundle (number) |

40 |

|

Dimensions of each band (cm) |

80 x 60 x 40 |

|

Weight of each bundle (tons) |

1 |